MIT engineers designed an affordable, reusable face mask that’s as effective as an N95 — take a look

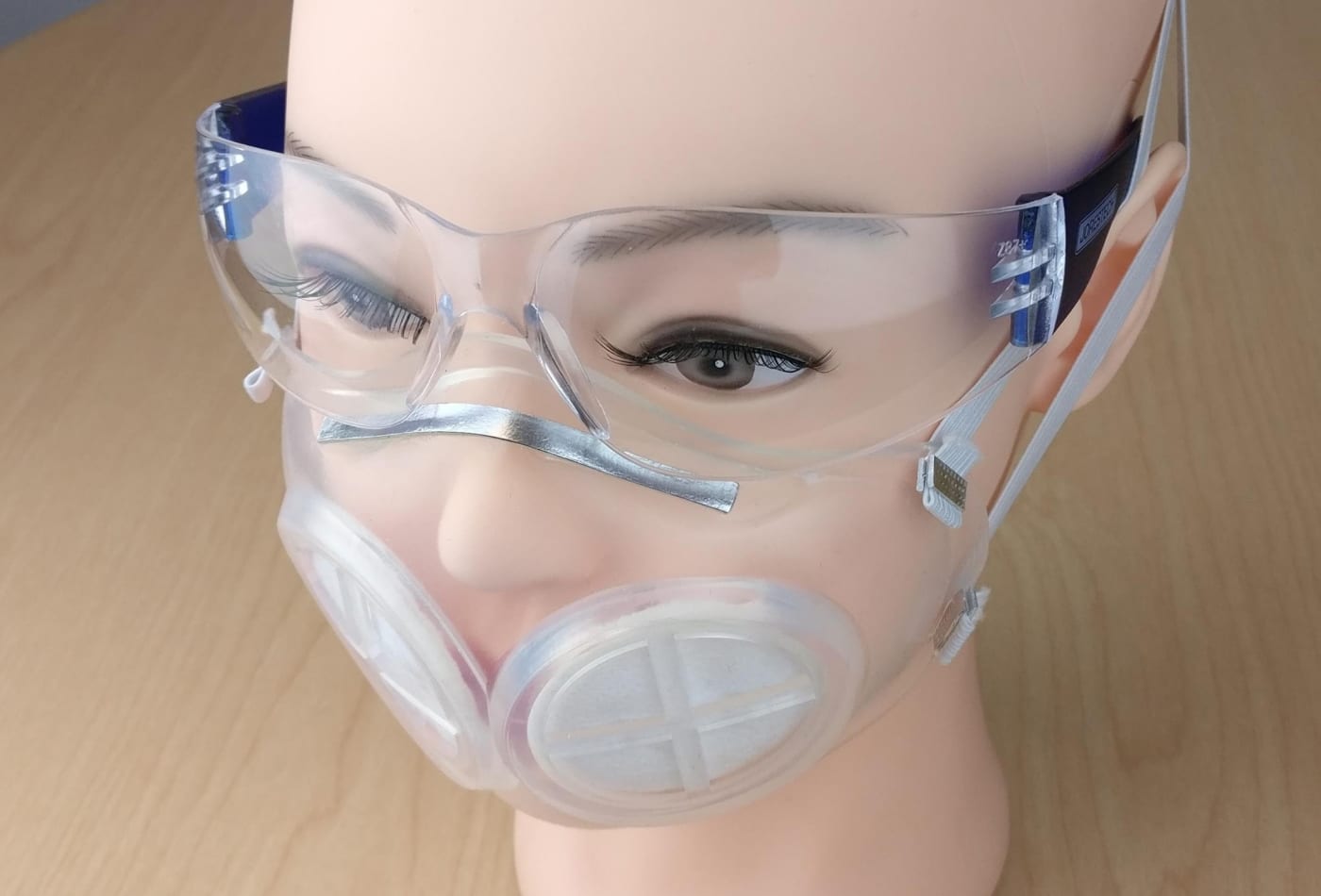

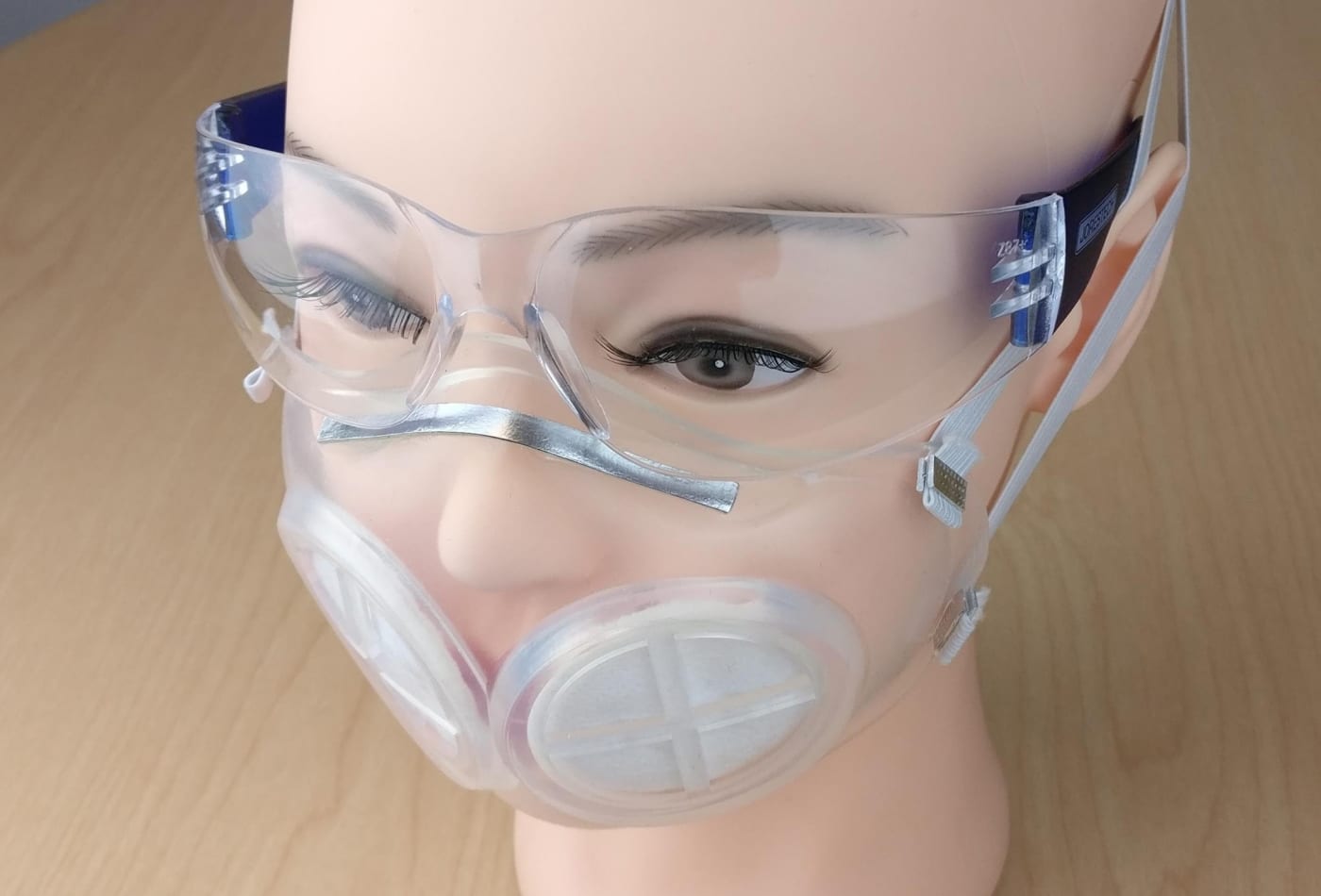

The iMASC is a clear rubber mask that covers the nose and mouth, with a nose bridge and two nylon elastic straps that go around the head. The fit was based on the 3M 1860 respirator, a particular style of N95 mask that’s commonly used by healthcare providers.

Courtesy of MIT.

At the beginning of the Covid-19 pandemic, the shortage of N95 respirator masks presented a dire situation for the healthcare and frontline workers who needed them most. Essential workers who relied on N95 masks had no choice but to wear what were meant to be disposable N95 masks for weeks at a time. Some started disinfecting the masks to be redistributed and reused.

Now, as Covid-19 infections surge and states such as Texas and Florida and hospitals and healthcare workers once again become overwhelmed with the volume of patients, N95 respirators still remain in short supply.

But engineers and researchers at MIT and Brigham and Women’s Hospital have a created a new type of face mask that could be a game-changer. In a laboratory setting, the prototype worked as well as a N95 respirator at filtering out virus-containing particles.

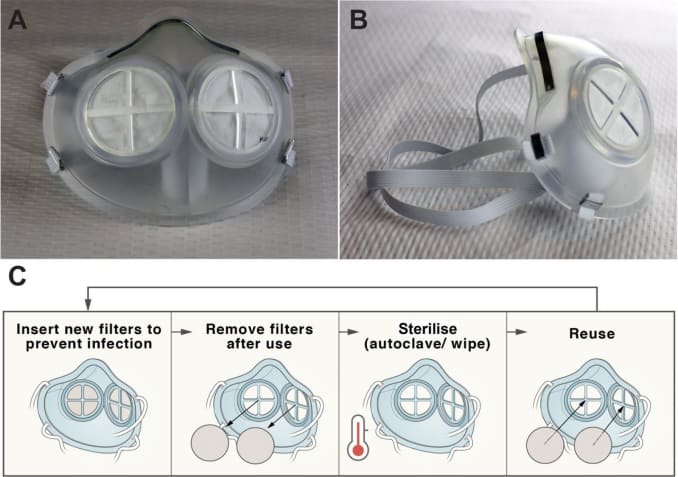

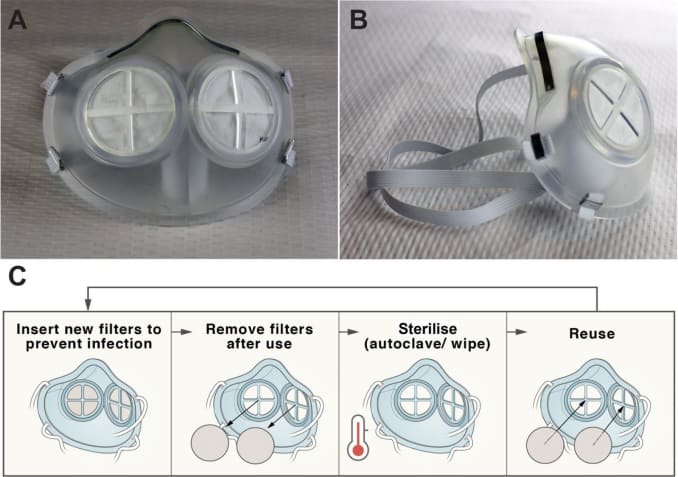

The biggest innovation? While N95 masks are made entirely from a special material that filters out airborne droplets and fluids that could contain the Covid-19 virus, the new MIT mask is made from silicone, with slots for just two small, disposable disks of the N95 material (which serve as filters). That means the masks themselves can be quickly and easily sterilized and reused, and though the small filters must be thrown out, each mask requires much less N95 material.

Called the iMASC, which stands for Injection Molded Autoclavable, Scalable, Conformable, this design could help solve shortage issues.

Small N95 filters can be easily placed inside the silicone mask.

Courtesy of MIT.

The new iMASC system can also be sterilized a few different ways without sacrificing its effectiveness, the researchers wrote in a paper published in the British Medical Journal Open. For example, researchers were able to use a steam sterilizer on the masks, put the masks in an oven, as well as soak them in both bleach and rubbing alcohol. (Treating used N95 masks with hydrogen peroxide disinfectants to neutralize any viruses requires special equipment and takes a few days. It also only allows the masks to be re-worn for one day at a time, up to 20 more times.)

The iMASC researchers “wanted to maximize the reusability of the system,” Giovanni Traverso, an MIT assistant professor of mechanical engineering and a gastroenterologist at Brigham and Women’s Hospital, said in a press release.

The new mask could also be more environmentally-friendly — it uses less disposable material, which produces much less waste than tossing a whole mask, Adam Wentworth, a research engineer at Brigham and Women’s Hospital and a research affiliate at the Koch Institute, said in a press release.

An N95 mask is typically constructed from polypropylene and polyester material that filters airborne particles.

(Photo by Nora Tam/South China Morning Post via Getty Images)

So far, the masks have proven effective and comfortable.

A group of 24 healthcare workers (including nurses, physicians and technicians) wore the new masks and completed tests that involved breathing, talking, moving their head and body and making facial expressions. The participants said that the mask fit well and felt breathable. Most importantly, the mask successfully filtered out a sugar solution in the air that was used to mimic aerosolized respiratory droplets.

More tests need to be done, and the group is currently working on a second mask design.

The team plans to eventually have the rubber mask approved by the Food and Drug Administration and the National Institute for Occupational Safety and Health. Once complete, the masks could cost hospitals $15 each, Fast Company reported. (N95 masks can cost between $2.80 and $6.95 per unit, according to data compiled by nonprofit Project N95.)

The ultimate goal is to make the masks available for healthcare workers as well as the general public, but there is no timeline as of yet.

译文:

麻省理工学院的工程师设计了一种价格可承受,可重复使用的面罩,其效果与N95一样好-看看

iMASC是一个透明的橡胶面罩,覆盖鼻子和嘴巴,带有鼻梁和两个缠绕在头部周围的尼龙弹性带。贴合性基于3M 1860防毒面具,这是医疗服务提供商常用的一种特殊样式的N95口罩。

由麻省理工学院提供。

在Covid-19大流行初期,N95防毒口罩的 短缺 给最需要它们的医护人员和一线工人带来了严峻的形势。依靠N95口罩的基本工人别无选择,只能一次 戴几本所谓的一次性N95口罩 。一些人开始 对口罩进行消毒,以重新分配和重复使用。

现在,随着Covid-19感染激增,得克萨斯州和佛罗里达州等州以及医院和医护人员再次不堪重负, N95呼吸器仍然 供不应求。

但是麻省理工学院和百灵医院的工程师和研究人员 创造了一种新型的口罩 ,可以改变游戏规则。在实验室环境中,该原型机与N95防毒面具在过滤掉含病毒的颗粒时一样有效。

最大的创新?N95口罩完全由特殊材料制成,可过滤掉可能含有Covid-19病毒的空气中的液滴和液体,而新型MIT口罩则由硅树脂制成,只有两个小而一次性的N95材料盘(用于放置磁盘)用作过滤器)。这意味着口罩本身可以快速,轻松地进行消毒和重复使用,尽管必须丢弃小型过滤器,但每个口罩所需的N95材料要少得多。

称为iMASC,代表可高压灭菌,可扩展,合格的注塑成型,该设计可以帮助解决短缺问题。

小型N95过滤器可轻松放置在硅胶面罩内。

由麻省理工学院提供。

研究人员在英国医学杂志公开赛上发表的一篇论文中写道,新的iMASC系统还可以通过几种不同的方式进行消毒而不牺牲其有效性 。例如,研究人员能够在口罩上使用蒸汽消毒器,将口罩放在烤箱中,然后将它们浸泡在漂白剂和酒精中。(用过氧化氢消毒剂处理用过的N95口罩 以中和任何病毒需要 花费几天的特殊设备。这也仅允许一次将口罩重新戴一天,最多再戴20次。)

该iMASC研究者“希望最大化系统的可重用性,”乔瓦尼特拉韦尔索,机械工程的麻省理工学院助理教授布里格姆妇女医院肠胃病,在上述 新闻稿。

布莱根妇女医院的研究工程师, 科赫研究所的研究人员亚当·温特沃斯(Adam Wentworth)表示,新面罩还可以更加环保-它使用的一次性材料更少,比扔掉整个面罩要少得多。新闻稿。

N95面罩通常由聚丙烯和聚酯材料制成,可过滤空气中的颗粒。

(Nora Tam /《南华早报》通过Getty Images拍摄)

到目前为止,口罩已被证明有效且舒适。

一组由24名医护人员(包括护士,医生和技术人员)戴上的新口罩,并完成了涉及呼吸,交谈,移动其头部和身体并进行面部表情的测试。参加者说,面罩贴合性好,透气。最重要的是,口罩成功地过滤了空气中的糖溶液,该溶液用于模拟雾化的呼吸道飞沫。

需要做更多的测试,该小组目前正在研究第二种掩模设计。

该小组计划最终使橡胶口罩获得美国食品药品监督管理局和美国国家职业安全与健康研究所的批准。《快速公司》 报道说,一旦面罩完工,每个医院的口罩可能要花费15美元 。(根据非营利组织Project N95汇编的数据,N95口罩每片的价格在$ 2.80至$ 6.95之间 。)

最终目的是使医护人员和普通大众都可以使用口罩,但目前尚无时间表。